3D Scanner : White Light vs Blue Light : Which One is Right for You?

3D scanner is one of the most revolutionary tool in 3D product development industry and when it comes to 3D scanning technology, there are several options available on the market. Two popular types of scanners are white light scanners and blue light scanners. In this article, we’ll take a closer look at these two technologies and compare them.

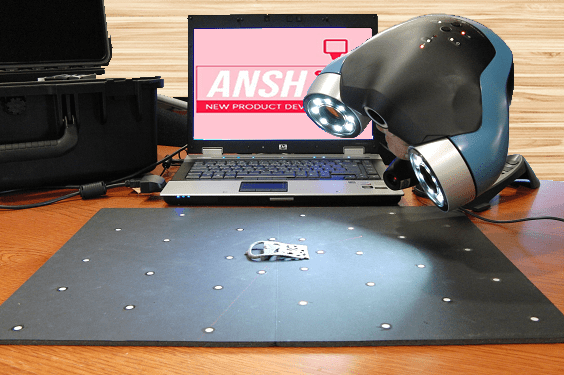

White Light Scanners:

White light scanners work by projecting a pattern of white light onto the object being scanned. The scanner then measures the distortion of the pattern caused by the object’s surface, which allows for a digital representation of the object to be created. White light scanners have been around for many years and have proven to be reliable and accurate. They are commonly used in industries such as aerospace, automotive, and medical.

White light scanners, also known as structured-light scanners, are a type of 3D scanning technology that use structured light patterns to capture highly accurate and detailed 3D representations of physical objects. These 3D scanner emit a series of light patterns onto the object being scanned, which are then recorded by one or more cameras positioned at different angles around the object.

The basic principle behind white light scanning is triangulation. As the light patterns are projected onto the object, they create a unique pattern of shadows and highlights on the surface of the object. The cameras capture these patterns from different angles, allowing the scanner software to calculate the precise 3D position of each point on the object’s surface based on the differences in the recorded light patterns.

White light scanners are capable of capturing incredibly detailed 3D models with high accuracy and resolution. They are particularly useful for scanning complex geometries and surfaces that may be difficult or impossible to capture using other types of 3D scanning technologies.

There are several types of white light scanners available on the market today, ranging from handheld devices to large, stationary systems. Handheld scanners are typically used for smaller objects, while larger systems are better suited for scanning larger objects or entire environments.

In addition to their high level of detail and accuracy, white light scanners offer several other advantages over other types of 3D scanning technologies. For example, they are non-contact, meaning that they do not require physical contact with the object being scanned, which can help prevent damage to delicate or valuable objects. They are also relatively fast, with some systems capable of scanning an object in just a few minutes.

Despite their many advantages, there are also some limitations to white light scanners. For example, they can struggle to capture reflective or transparent surfaces accurately, as well as objects with highly complex geometries. Additionally, they can be relatively expensive compared to other types of 3D scanning technologies.

Overall, white light scanners are a powerful and versatile tool for capturing detailed 3D representations of physical objects. They are widely used in industries such as manufacturing, design, and engineering, where accurate and detailed 3D models are essential for creating high-quality products and designs.

Blue Light Scanners:

Blue light scanners, on the other hand, use a high-intensity blue light to scan the object. Like white light scanners, they project a pattern onto the object and measure distortions to create a digital model. However, blue light scanners have some advantages over white light scanners. For one, blue light is less sensitive to ambient lighting conditions, which means that they can be used in a wider range of environments. Additionally, blue light scanners tend to produce more accurate results when scanning shiny or reflective surfaces.

Blue light scanners are a type of 3D scanning technology that use blue light to capture highly accurate and detailed 3D models of physical objects. These scanners emit a narrow band of blue light onto the object being scanned, which is then captured by one or more cameras positioned at different angles around the object.

The basic principle behind blue light scanning is similar to that of white light scanning, in that it uses triangulation to calculate the precise 3D position of each point on the object’s surface. However, blue light scanning offers several advantages over white light scanning.

One of the key advantages of blue light scanning is its ability to capture highly accurate and detailed 3D models of small and intricate objects. Blue light has a shorter wavelength than white light, which allows for more precise measurements of small features and details on the surface of an object.

Another advantage of blue light scanning is its ability to capture high-quality data even on reflective or transparent surfaces. Unlike white light scanners, which can struggle to capture accurate data on these types of surfaces, blue light scanners use a special filter that blocks out any reflections or glare caused by ambient light.

Blue light scanners are also relatively fast, with some systems capable of capturing a 3D model in just a few seconds. This makes them well-suited for use in manufacturing and quality control applications where speed is important.

There are several types of blue light scanners available on the market today, ranging from handheld devices to large, stationary systems. Handheld scanners are typically used for smaller objects, while larger systems are better suited for scanning larger objects or entire environments.

Despite their many advantages, there are also some limitations to blue light scanners. For example, they can struggle to capture accurate data on objects with highly complex geometries or surfaces that are difficult to access. Additionally, they can be relatively expensive compared to other types of 3D scanning technologies.

Overall, blue light scanners are a powerful tool for capturing highly accurate and detailed 3D models of physical objects. They are widely used in industries such as manufacturing, design, and engineering, where precise measurements and detailed models are essential for creating high-quality products and designs.

So Which One Should You Choose?

The answer to this question really depends on your specific application. If you’ll be scanning objects in a controlled environment with consistent lighting conditions and non-reflective surfaces, then a white light scanner may be sufficient. On the other hand, if you need to scan objects in various environments with shiny or reflective surfaces, then a blue light scanner might be the better choice.

It’s also worth noting that blue light scanners tend to be more expensive than white light scanners. So, if cost is a concern, then a white light scanner could be the way to go.

In Conclusion:

Both white light scanners and blue light scanners have their advantages and disadvantages. Ultimately, the choice between the two will depend on your specific needs and budget. If you’re unsure which type of scanner is right for you, it may be helpful to consult with a 3D scanning expert who can help guide you in the right direction.