Fluid Analysis

Fluid Analysis at ANSH 3D

ANSH 3D Product Development uses Computational Fluid Dynamics for our clients who need to make better, faster decisions. Our CFD simulation products have been validated and are highly regarded for their superior computing power and accurate results. We are known to reduce development time and effort while improving your product’s performance and safety.

ANSH 3D is a fluid analysis company that specializes in providing cutting-edge solutions for the analysis and simulation of fluid systems. They leverage advanced computational fluid dynamics (CFD) software to create accurate models of complex fluid systems, allowing clients to optimize their design and performance.

ANSH 3D’s team of experts has extensive experience in fluid dynamics, numerical methods, and engineering design. They work closely with clients to understand their specific needs and provide custom solutions tailored to their requirements.

The company’s services range from basic CFD simulations to more advanced multiphysics modeling, which combines multiple physics phenomena such as fluid flow, heat transfer, and chemical reactions. ANSH 3D also offers consulting services to help clients interpret and analyze their simulation results, and make informed decisions based on the insights gained from the simulations.

Overall, ANSH 3D is dedicated to delivering high-quality, innovative fluid analysis solutions that enable clients to optimize their systems, reduce costs, and improve overall performance.

What Is Fluid Analysis?

Fluid analysis, also known as computational fluid dynamics (CFD), is a scientific and engineering technique used to study the behavior of fluids, such as air and liquids, in motion. It involves the use of powerful mathematical algorithms and computer simulations to predict how fluids will behave in various scenarios.

Applications of Fluid Analysis

Fluid analysis has numerous applications across various industries, including aerospace, automotive, energy, environmental, and biomedical. For instance, CFD can be used to analyze the aerodynamics of aircraft, design more efficient engines for cars, optimize wind turbines for renewable energy, and model blood flow in the human body.

How Fluid Analysis Works

Fluid analysis begins with the creation of a mathematical model that describes the fluid system being studied. This model can be as simple or complex as needed, depending on the level of detail required for the analysis. Once the model is created, it is fed into specialized software that uses numerical methods to solve the equations governing the behavior of the fluid.

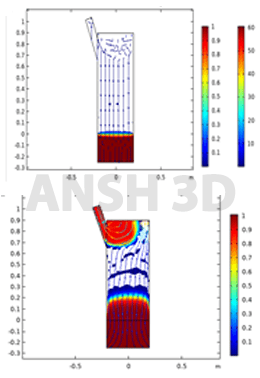

The software breaks down the fluid system into millions of tiny cells and calculates the velocity, pressure, temperature, and other properties of the fluid at each cell. By analyzing this data, engineers can gain insights into how the fluid behaves under different conditions and identify areas where improvements can be made.

Benefits of Fluid Analysis

There are several benefits to using fluid analysis techniques such as CFD:

1. Improved Efficiency: By simulating fluid behavior in different scenarios, engineers can identify areas where the fluid is not flowing efficiently and make changes to the design to optimize performance. This can result in significant cost savings and improved energy efficiency.

2. Reduced Risk: Fluid analysis allows engineers to test new designs and modifications virtually before implementing them in the real world. This reduces the risk of expensive mistakes and ensures that the final product meets all requirements.

3. Faster Time-to-Market: Using CFD and other fluid analysis tools can significantly reduce the time it takes to develop and test new products. This is because virtual testing can be conducted more quickly and iteratively than physical testing.

4. Greater Insight: CFD simulations provide engineers with a wealth of data about fluid behavior that would not be possible to obtain through physical testing alone. This allows for greater insight into the underlying physics of the system and helps identify areas for further optimization.

Conclusion

Fluid analysis is a powerful tool that enables engineers to optimize the performance of fluid systems across a wide range of industries. By simulating fluid behavior in different scenarios, engineers can gain insights into how the system works and identify areas for improvement. As computational power continues to increase and software becomes more sophisticated, the potential applications of fluid analysis will only continue to expand.

Process Of Fluid Analysis at ANSH 3D

Fluid simulation harnesses Computational Fluid Dynamics (CFD) to analyze an entire fluid volume.

Step 1:- Importing data into our CFD analysis software

Our designers will extract the fluid volume from a client’s CAD software and import it directly into our CFD analysis software.

Step 2:- Assignment of inlets and outlets

Next, we assign inlets and outlets, we enter the known velocity, flow rate, or pressure values and we establish walls around the fluid.

Step 3:- Execution of fluid analysis

The software will then solve for the velocities and pressures at every point in the fluid, and these quantities are post-processed using a variety of methods. In some cases, it is common to include solid volumes as well as fluid volumes in the analysis, to determine the forces that are affecting your structures.

When it comes to fluid simulation, our biggest value addition is our ability to clearly interpret and communicate these results to our clients.